Flexible Jaw Coupling

contact usProfessional machinery & Manufacturer

MISSION

Use our knowledge to make the world’s industries work better.

VISION

Be the global leader in bearings and mechanical power transmission, continually improving performance, reliability and efficiency.

VALUES

Ethics & Integrity

Quality

Teamwork

Excellence

WE ARE ONE OF THE BEST MANUFACTURER AND SUPPLIER IN CHINA, CHOOSE QUALITY MANUFACTURERS, SUPPLIERS, EXPORTERS AT EVER-POWER.NET

SURFACE TREATMENT

Annealing, natural canonization, heat treatment, polishing, nickel plating, chrome plating, zinc plating,yellow passivization, gold passivization, satin, Black surface painted etc.

QC & CERTIFICATE

Technicians self-check in production,final-check before package by professional Quality inspector

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

5W+

Total factory is 50,000 square meters

All About Flexible Jaw Couplings

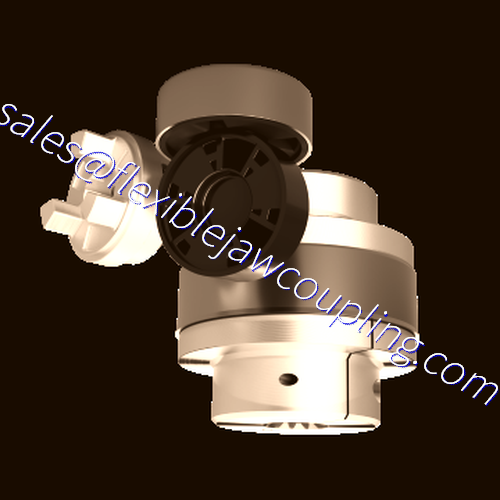

Flexible jaw couplings are three-piece flexible shaft couplings that are used to connect driving and driven shafts in mechanical power transmission assemblies. Flexible jaw couplings are used to counter the inevitable misalignment that occurs between connected shafts and in some cases absorb shock. Other flexible jaw coupling styles included Oldham, Schmidt, chain, disc, bellows, grid, and beam, about which more may be found in our flexible jaw couplings Buyers Guide.

Applications

Flexible jaw couplings are commonly employed on large, industrial machines such as pumps, blowers, compressors, mixers, etc. They are also used in smaller motion control systems, although special considerations are necessary.

For standard power transmission applications, flexible jaw couplings are available in a broad range of shaft sizes and torque capacities, with typical bore diameters from 1/8 to 7 in. and torques from 3-1/2 to 170,000 in.-lbs. available. Flexible jaw couplings are designed to operate without lubricant in many instances and function well in the presence of dirt and other particulates. Jaws can be manufactured in steel, aluminum, and stainless steel and often in bronze, ductile iron, and powdered metal. Spiders may be made of polyurethane, natural rubber, urethane, Hytrel®1, and, in special cases, soft metals such as bronze for low speed, high torque applications.

flexible jaw couplings

The Basics of Flexible Jaw Coupling Technology

Flexible Jaw couplings are generally used to connect continuous-duty electric motors with driven machinery, pumps, and gearboxes. They typically accommodate angular shaft misalignment up to 1 degree and parallel misalignment up to 0.015 in.

All elastomeric flexible jaw couplings are classified according to how their elastomeric elements transmit torque between driving and driven hubs — the elements is either in compression or shear.

In flexible jaw couplings, the element is loaded in compression between the jaws of mating hubs. These jaws operate in the same plane, with the driving hub jaws pushing toward the driven hub jaws. Legs of the elastomeric spider transmit and cushion the force between the driving and driven jaws by being compressed between them.

This contrasts to shear-type flexible jaw couplings, in which driving and driven hubs operate in separate planes, with the driving hub pulling the driven hub through an elastomeric element suspended between them. Here, the element transmits and cushions the force between the hubs by being stretched between them.

Capabilities

Compression type couplings offer advantages in four areas: load capacity, torsional stiffness, safety, and easy installation. First, all elastomers — especially synthetic rubber — have higher load capacity in compression than they do in shear. Therefore, compression types transmit torque and tolerate more overload than shear types. Heavy-duty jaw models with up to seven jaws handle torque ranges up to 170,000 lb-in.

Second, compression types offer more torsional stiffness (less twist between hubs) than shear types, with some versions closely approaching the very stiff characteristic of metallic flexible jaw couplings. This high torsional stiffness minimizes backlash between motor and driven machine, offering near-equal movement of the driven shaft for each incremental movement of the driving shaft, an important factor in certain conveyor and pump applications.

Third,flexible jaw couplings are fail-safe: the coupling can still operate even if the spider breaks. The driving jaws simply rotate until they contact the driven jaws directly, and the flexible jaw coupling continues to function (albeit with considerable noise and accelerated wear). Maintenance personnel can thus replace the spider at a convenient time, which may prevent critical system downtime. For this reason, the jaws in a well-designed and manufactured flexible jaw coupling withstand several times the coupling’s torque rating.

Fourth, the simple three-piece assembly — a spider sandwiched between metal hubs — makes these units easy to install and inspect. The contoured spider usually allows “blind fit” even in the most confined spaces.